Sliding pocket door systems

Sliding pocket door systems provide an important benefit compared to traditional hinged doors, saving the functional space needed for the door opening (aperture radius). We can use them if we want not only to optimise the use of space in a small house but also to gain space for furniture in bigger apartments.

Sliding pocket door systems’ world

Pocket door frames type

Our ranges

How do you calculate the dimensions of a sliding pocket door system?

SLIDING POCKET DOOR SYSTEMS’ WORLD

HOW DOES A SLIDING DOOR WORK?

Someone calls them pocket door frames, others simply sliding doors, or sliding door systems: no matter how you call it, but a sliding pocket door system for interiors represents the undisputed protagonist within furniture both when a renovation is required or in the construction of new buildings. The biggest advantage of this system is to offer additional living space in a home (+8% of floor area), without compromising individual stylistic preferences; as a matter of fact sliding pocket door systems can match any decorating feature, from classic and contemporary furnishing, up to a modern style. The system is made of two main elements: the door, well visible and familiar to the user, and the pocket which lives inside the wall, hidden from sight, ready to host the sliding door when it opens.

WHAT IS A POCKET DOOR SYSTEM?

A sliding pocket door system is a metal frame with a pocket box, that allows the setup of any door and is made to be integrated into the wall to host the door when open. You can install a pocket door system in any wall in the house, except the bearing walls or those that host chimneys. However, there is always a way to install a pocket door system: it is possible to create a false plasterboard wall next to the original wall and let the door slide in it rather than into the structural walls. A pocket door system, called “cassonetto” in Italian, is not visible but it has an important role in our homes, making them strong, comfortable and safe.

“The most meaningful things are often hidden from the eye. The pocket door systems for interiors fulfil your dreams away from the spotlight, ensuring that everything goes in perfect accordance with best expectations.”

WHAT IS A POCKET DOOR FRAME MADE OF?

The production process that leads to a pocket door system is a long path that transforms the raw material into a product that is characterised by parts made to ease the job of the installer, as well as the final users’. The raw source of a pocket door system is a metal coil. This material is a roll of metal sheets in different sizes sourced from Italian steel industries. The different dimensions of the sheets determine the width of the pocket. The cut-to-measure process of these metal ribbons, instead, determines the height of the pocket. Two zinc coated steel sheets make the two sides of the pocket.

DOUBLE-STAVED VERTICAL PROFILE

Once the sheet is cut to size, it goes through the profiling machine, which transforms through a special machining process the flat sheet into a staved one, making it sturdy.

The double-staved vertical profiles are 4mm and 2mm high, and 50mm spaced, and they ensure the best structural robustness to the system.

HORIZONTAL REINFORCEMENT BARS

Once the metal sheet is turned into a structured steel leaf, it is subjected to a clinching process in which 6 horizontal reinforcement bars are fixed to every panel (12 per pocket).

These slats, applied on both systems for plasterboard walls and plastered walls, ensure shape retaining to the leafs and stress-resistance to the lateral pressures.

OVERLAPPING PLASTER MESH

In the version for plastered walls, the horizontal reinforcement slats are useful to hang, through specific slots, the plaster tight-mesh net ( 50x30 mm). This overlapping mesh allows an easier grab of the plaster to the system, ensuring a perfect finish of the wall.

ASSEMBLING

A roller conveyor then carries the profiled leaves (which include the net in the version for plastered wall) to the assembly phase. In the first step all the elements that are useful to the last steps of installation are inserted inside the pocket. These components are:

CROSSBAR RAIL

This element is the top edge of the passage opening and hosts a sliding track kit that hangs the door. The “easyclip” system makes really easy and fast joining the crossbar rail to the pocket.

ANODISED ALUMINIUM RAIL

The rail allows the trolleys to slide fluidly and smoothly operate the door, opening and closing the passage. The special “design-saving” flaps add aesthetic value to this piece, since you only see the best of the product.

EASY-ROLL NYLON TROLLEY KIT

The sliding gears are connected to the door so that it can run softly. The wheels are silent because they are equipped of sealed ball bearings and they have a 100 kg guaranteed and certified weight capacity. The capacity can be extended to 120 kg with another accessory: 120 kg trolley kit.

SPACE BARS

The two spacers, central and lower, ease the setup of the system, keeping it straight and true to floor level.

POCKET DOOR FRAMES TYPES

DIFFERENT NEEDS, DIFFERENT SOLUTIONS

There are different kinds of sliding pocket door systems, which meet specific structural and aesthetic needs in houses, such as: a plasterboard wall or brick wall.

Plaster is a building material used to cover the walls to protect them but also to give them a better finish. Italian buildings are generally made of brick walls. This system is often used to create walls that support and resist loads, such as the bathroom and kitchen walls. The plastered walls sustain strong forces, so you can put wall furniture.

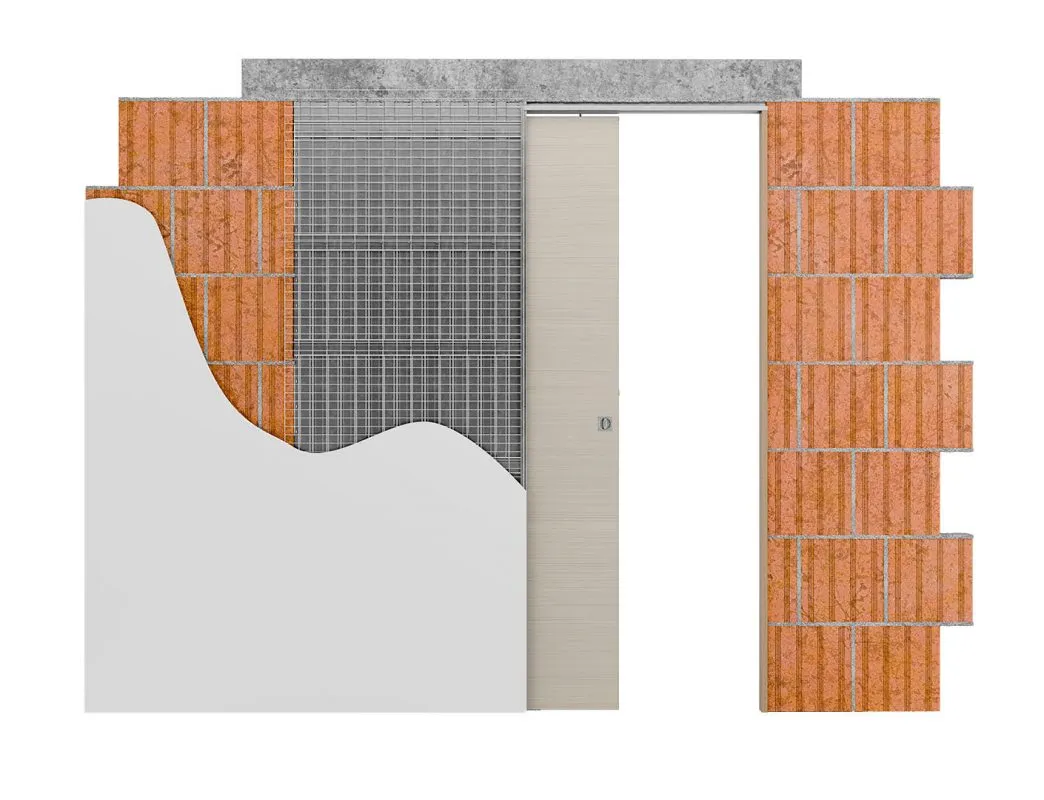

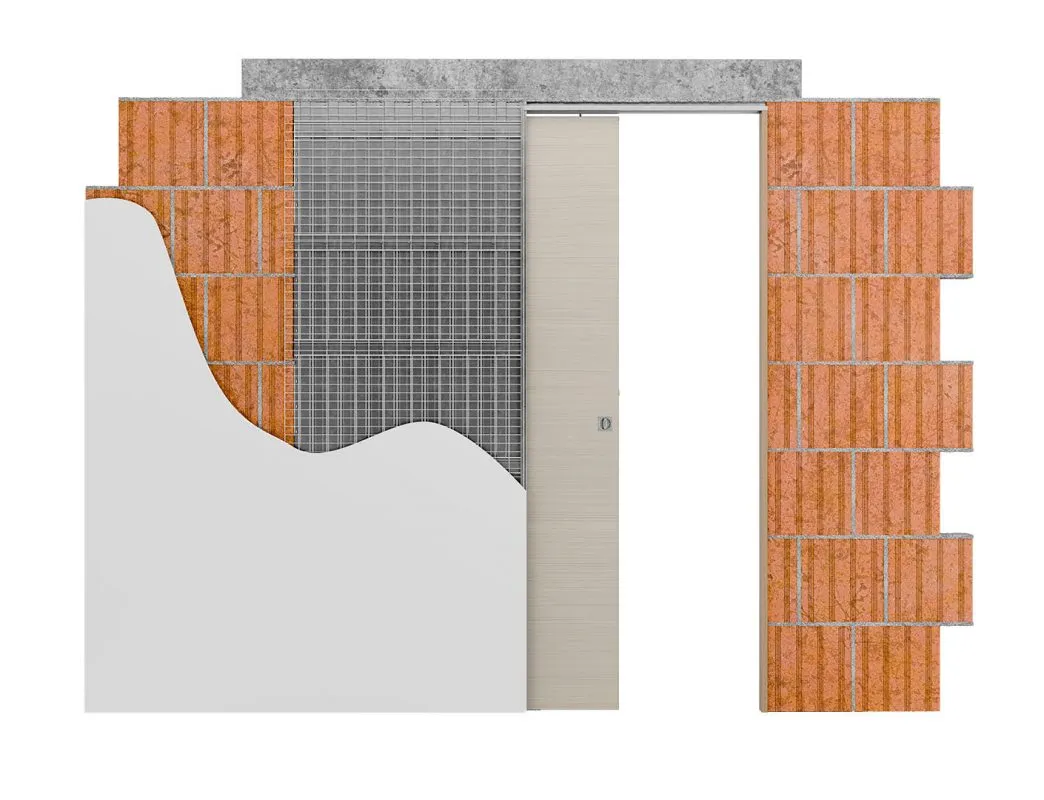

POCKET DOOR SYSTEM FOR PLASTERED WALLS

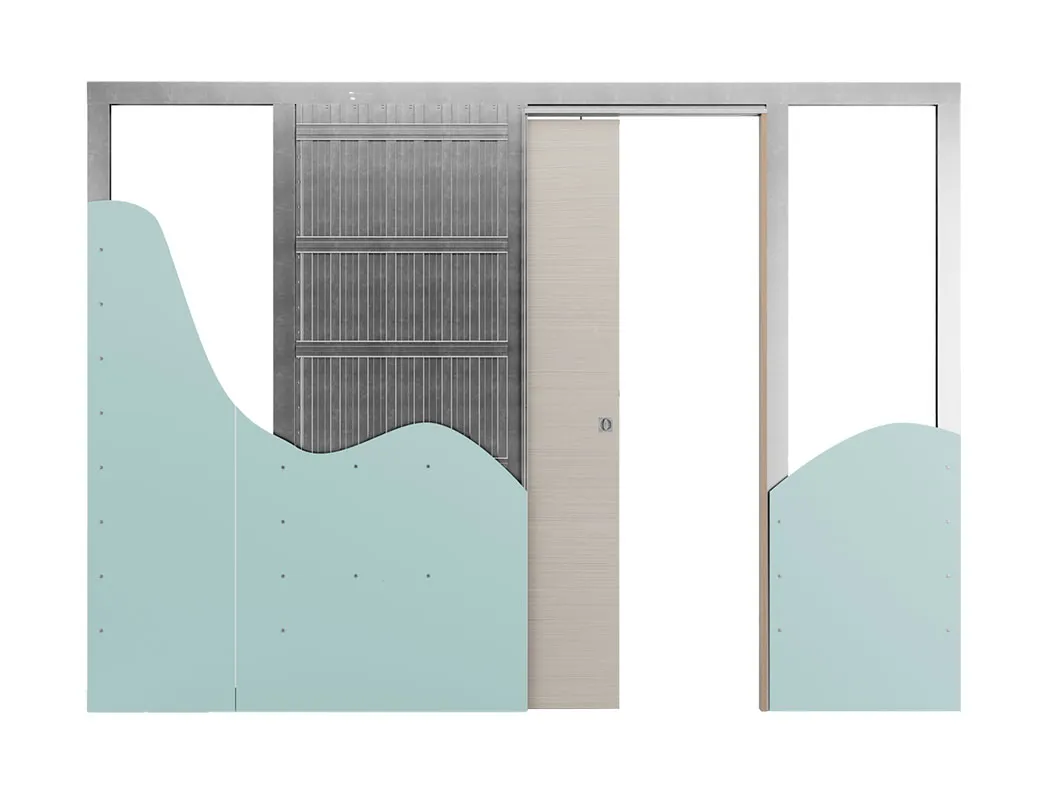

Plasterboard walls are usually thinner than plastered walls as they are made of external plasterboard sheets set on an aluminium studwork that normally is filled of sound-absorbing insulating material. Moreover, plasterboard structures can change the shape of a room without creating definitive walls.

POCKET DOOR SYSTEM FOR PLASTERBOARD WALLS

ASSEMBLED POCKET DOOR SYSTEM OR KIT VERSION?

A pocket door system can be supplied in two versions: pre-assembled or in kit to be set up on the spot.

POCKET DOOR SYSTEM

POCKET DOOR SYSTEM IN KIT

Advantages of a pocket door system in kit

Less bulky in warehouse

Easy and quick to install

Removable rail

Reinforced vertical profiles

SINGLE DOOR OR DOUBLE DOOR?

You can install a single door or have a pocket system for a double door.

POCKET DOOR SYSTEM SINGLE DOOR

POCKET DOOR SYSTEM DOUBLE DOOR

CAN I MAKE A DOUBLE DOOR FROM TWO SINGLE DOORS?

In the case of a first purchase, it is advisable to buy a double pocket door system: it will save time because it is already set for the installation of two doors. Otherwise, if there are two single pocket door systems that need to become a double door system, it is possible to join them through a specific junction bracket. This accessory is called junction kit for double door, and supplied together with adjustable spacers.

TECHNICAL AND DESIGN PRODUCTS FOR EVERY OCCASION

BIG OPENINGS

Pocket door system for telescopic doors

SAVE SPACE

Two sliding doors in the same pocket

LIGHT POINTS

Sliding pocket door system set for electrical wires

CURVED WALL

Curved pocket door system

OUR RANGES

FLUSH TO WALL RANGE

no jambs and architraves

CLASSIC RANGE

with jambs and architraves

DOORS RANGE

made of wood or wood and aluminium

HOW DO YOU CALCULATE THE DIMENSIONS OF A SLIDING POCKET DOOR SYSTEM?

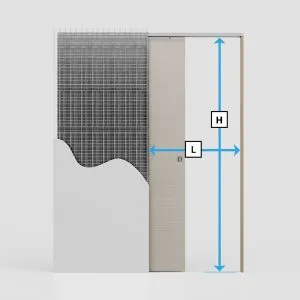

When you choose a sliding pocket door system it is extremely important to verify carefully all the sizes for a correct installation, before the order is placed.

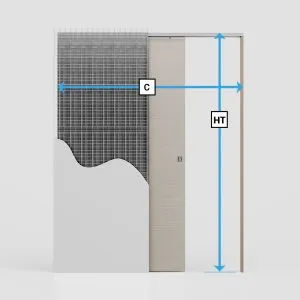

Here are some useful terms that help understand which dimensions should be considered:

Passage opening (light opening, doorway): it is the visible space when the work is completed, the doorway that separates or joins one room to the other. Put in technical but simple terms, the passage opening is the dimension between the striking jamb and the entrance of the pocket (passage width), as well as the dimension between the floor level and the crossbar (passage height).

Overall dimension: it is the space needed to install the full pocket door system. It includes the dimension of the door and the size of the pocket system for sliding door. This dimension is not only what you see when the work is finished, but also what is hidden inside the walls. The overall length can be calculated adding a technical quote to the sum of passage opening size in length and the size of the pocket. The overall height is the space between the floor level and the top of the crossbar.

PASSAGE OPENING

OVERALL DIMENSION

Standard dimensions of sliding pocket doors do not differ from the classic hinged ones. As for standard, we mean passage openings that go from 70 cm to 90 cm and a standard height of 210 cm.Any door frame - be it a sliding door with jambs and architraves or a stylish flush-to-wall model - can be customised. Generally speaking, a pocket door system can be customized in its dimensions from 60 cm to 150 cm for the length and up and over 270 cm for the height, which means as high as the ceiling. Do you want to know which pocket door system is the right one for you? Try our configurator. Insert the dimensions of your passage opening or your overall dimension and you will discover a world of solutions offered by Ermetika to make your home unique.

FILL THE FORM TO RECEIVE TECHNICAL ASSISTANCE

Send us an email to ask for further technical information about our products, for assistance or practical advice about your specific needs.